Long ago, when tubes ruled and Bell Labs dreamt of sending electrons through solid materials instead of a vacuum, few consumer audio products had circuit boards.

Though today PCBs (printed circuit boards) are common, back in the 50s they were rare, though hardly unknown. Over 100 years ago in 1903, German inventor, Albert Hanson, came up with the idea of incorporating flat foil conductors by gluing multiple layers of thin metal to an insulating board. It worked, but was hardly a practical solution. Even Thomas Edison experimented with the more common approach of plating conductors throughout the early 1900s. Eventually, credit for the PCB goes to Arthur Berry and Max Schoop who together patented the print-and-etch method in the UK and United States respectively.

What this means is simple. Instead of the earliest attempts of adding to a piece of insulating material the thin strips of copper that would carry the electric currents, today’s PCBs are made by removing all the unwanted copper. You start with a fiberglass sheet (the insulator) that has a layer of copper glued onto it. By means of a printing process, the areas of copper we wish to keep are painted with a type of coating that acid won’t bother. The plate is then immersed in an (essentially) acid bath (ferric chloride) and anything not painted is eaten away. What you’re left with is the conductors to make the circuit work.

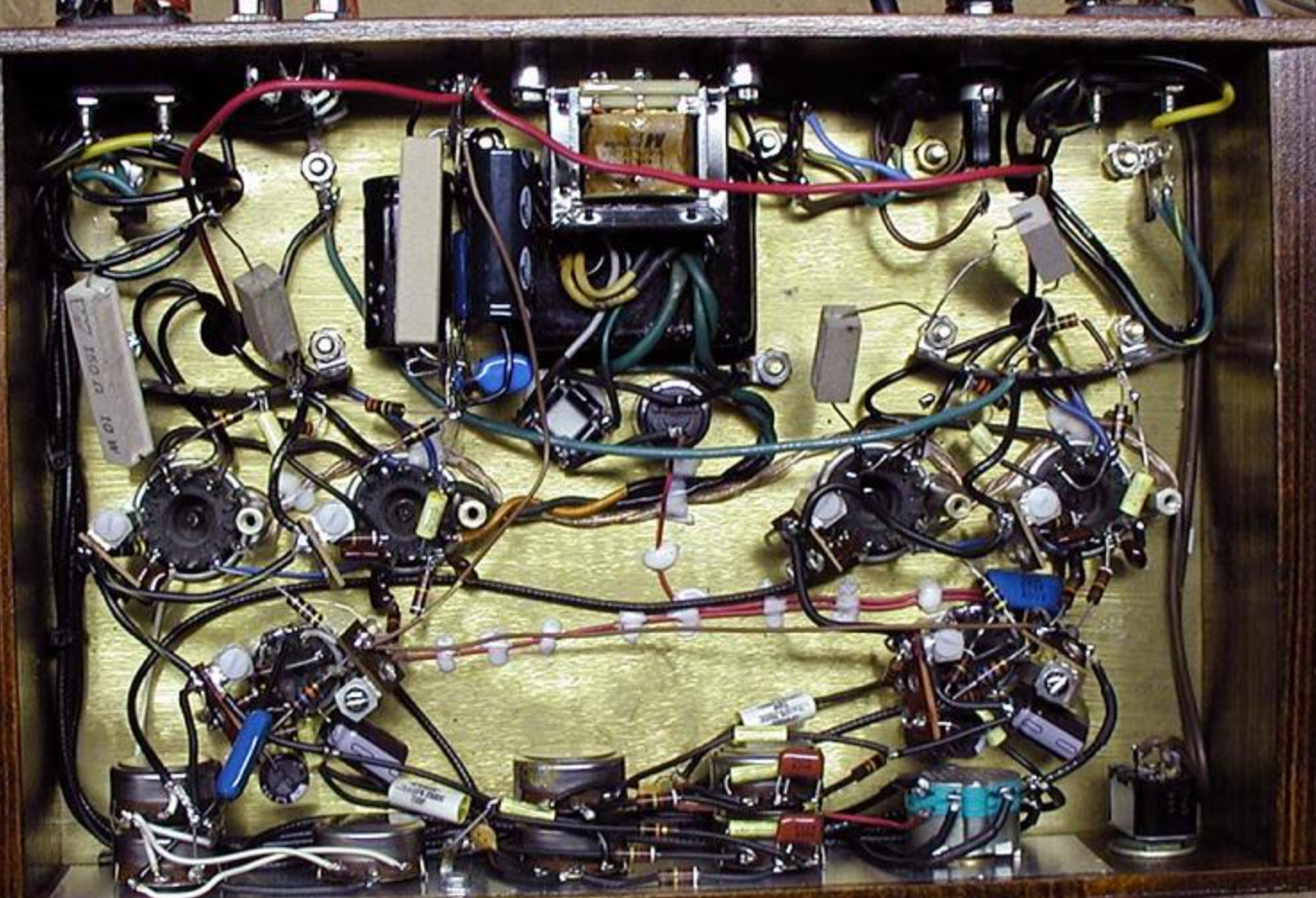

Before PCB technology was popularized, our audio circuits were hand-wired in a process known as point-to-point wiring. Tube sockets and capacitors had small eyelets where technicians could wrap wire and then solder the connection. Though cumbersome at best, this point-to-point wiring was a definite plus when it came to sound quality.

Today, of course, it is impossible to wire between points as the circuitry and bits and bobs that make it all work are microscopic.

But, back in the day, it was some really cool techniques.

PAUL McGOWAN / PS AUDIO